An F1 clutch is a tiny piece of engineering that completes an amazing job of transmitting the 800+ horsepower from the powertrain through the gearbox. Weighing less than 1.3kg and just 97mm in diameter, the tiny clutch is tortured every time the car pulls away at; race starts, pit stops and leaving the garage. Here we can have a close look at contemporary Clutch technology with this AP Racing clutch.

An F1 clutch is a tiny piece of engineering that completes an amazing job of transmitting the 800+ horsepower from the powertrain through the gearbox. Weighing less than 1.3kg and just 97mm in diameter, the tiny clutch is tortured every time the car pulls away at; race starts, pit stops and leaving the garage. Here we can have a close look at contemporary Clutch technology with this AP Racing clutch.

Clutch anatomy

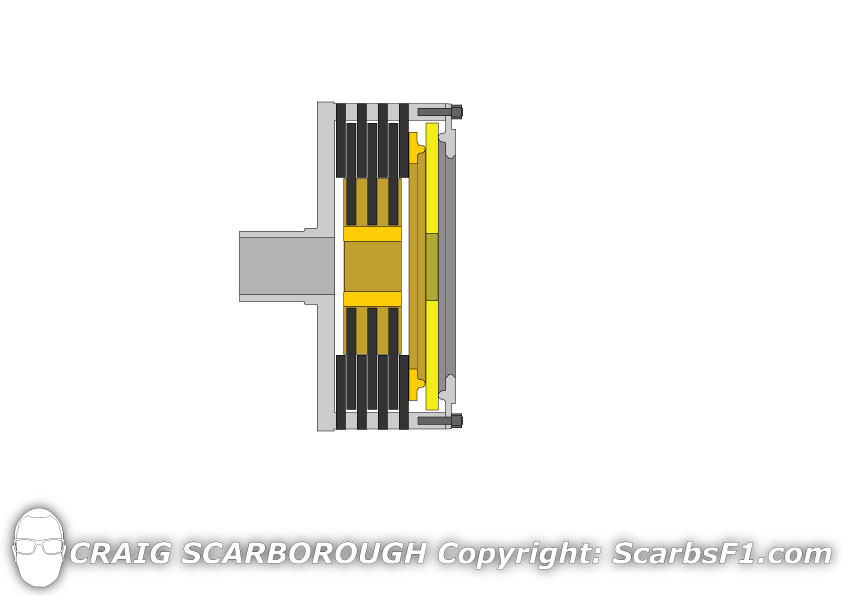

Mounted to the gearbox, the clutch separates the engine from the transmission. It is solely under the control of the driver via the steering wheel paddles, although the clutch is moved by the cars main hydraulic control system.

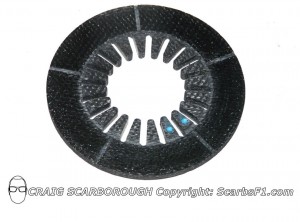

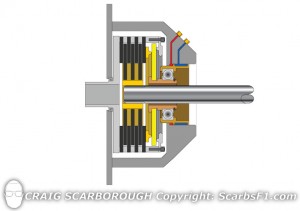

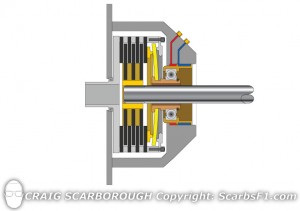

In detail, the clutch is made up of relatively few components; the basket, the inner and outer clutch plates, springs, the hub and the closing plate. In comparison to a road car or even most other race cars, the F1 clutch is tiny.

This size aids the engine designers who are not constrained by a large diameter clutch and can lower the entire engine to the lowest height the crankshaft will allow. However, since the F1 crankshaft height is now set by the rules at 56mm, even smaller clutches are no longer required. A small light clutch will have lower inertia and weigh less overall. While this small size is a boon for chassis and engine designers, the transmission designer is faced with a problem.

The clamping force created by the clutch is critical to ensure the engine horsepower is transmitted without slip. Clamping force is a product of the combined plate area and the clutch spring stiffness. Thus more plates or larger plates are required to ensure the clutch can withstand the loads without excessively heavy springs.

Due to this tiny size, the clutch produces an enormous amount of friction within a tiny amount of space, so heat is the huge design issue for the clutch designer. As with F1 brakes, which experience similar high temperatures and demands for low weight, carbon fibre is also the material used for the clutch’s friction surfaces. The four pairs of tiny clutch plates are just 4mm thin.

The outer plates are slotted into the sides of the titanium basket, while the inner plates are slotted on to an aluminium hub. This provides a surface area available for clamping of just 33 cm2 for each plate, the clutch in total has 200cm2 of combined clamping area.

..

The titanium closing plate attaches to the basket with two fasteners on each finger of the basket. Tiny 4mm nuts are used to close the clutch assembly, some teams will use these nuts as a mean to measure gearbox input rpm and even the angular position in order to time the seamless gearshifts accurately. This particular clutch also has a toothed ring fitted to the back of the basket, most likely for that similar purpose.

The other component within the clutch is the spacer ring that sets the initial clamping load accurately, this is accurately machined to specific thickness, in this clutch’s case the plate is 5.7mm thin.

As well as acting as a spacer, the ring also forms the fulcrum that the clutch diaphragm spring pivots on. The centre of the spring is circlipped to the cylinder on the clutch release actuator.

Clutch “PULL” Release (Clutch Diaphragm spring – yellow)

F1 uses clutches of the ‘pull’ type, which is where the slave cylinder moves away from the clutch to disengage the spring force that keeps the clutch clamped shut. This set up can provide more control compared to a push type clutch. Thus the clutch is usually enclosed by a spider or casing that mounts the slave cylinder in front of the clutch. We will look at a clutch operating mechanism in detail in a later post.

When the clutch actuator pulls to disengage the clutch, the fingers of the spring bend around the fulcrum and the pressure on the plates is released. This clutch movement is around 4mm, so the control required to go from engaged to bite point and disengaged is incredibly important. Friction from the spring rubbing on the clutch basket or fulcrum will make clutch control less predictable. Teams will focus on this area to improve clutch control, as it makes the race starts more predictable.

Clutch use

The clutch is hardly used on an F1 car, during upshifts and downshifts with modern Seamless shift techniques, the clutch is not required. Only when pulling away from the garage, pit stop of race start is the clutch needed. Clutch movement must be controlled solely by the driver, which is done by paddles on the steering wheel. These paddles use a rotary sensor to detect the paddle movement, unlike the gear shift paddles which use Hall Effect or Micro switches for the momentary switch effect. The rules explain at length how the clutch control must be achieved, but largely the paddle movement must be directly proportional to the clutch movement. Two clutch paddles are used, both for ease of use, especially when in a spin and for the dual release stages when launching the car at the start of the race.

Any slip of the clutch will send the clutch temperatures rocketing as the plates slip and create friction. Being made of the same carbon fibre as the brakes, the plates can glow red as their temperatures rise to some 900c. Excessive slip will overheat the clutch and prematurely wear the plates by the oxidization of their surface. With such tiny clutch movement, excessive wear will soon render the clutch unusable.

To ease both wear and promote a fast start with low wheel spin, teams often will release the clutch at relatively low RPM for less torque. This in contrast to the boy-racer style of max revs and sudden clutch release, this aggressive method can lead to some very fast starts, but often wheel spin and overheated clutched make this ales consistent approach. The lower torque low produced at 13k rpm (Kimi reported a practice start at Monaco at 13.2krpm) tends to produce a start that is almost as fast, but more consistent, as well as being kinder to the clutch and transmission.

The only time the clutch control is taken away from the driver and given to the electronics\hydraulic control systems is when the car detects a stall. If revs are too low for the clutch to be released or when the car is in a spin, the SECU detects the revs drop and the anti-stall system kicks in. This legal system will disengage the clutch and raise the throttle to a fast idle; the driver has to reset the system in order to regain control of the clutch. So effective are these systems, that we rarely see a car retired because it has stalled at the start or after spin.

Bite Point Find (BPF)

During the warm up laps, we often hear the engineer ask the driver to complete a clutch Bite Point Find (BPF), this is a process that records the bite point for the clutch, so that the launch sequence can be as fast as possible.

Just like a carbon-carbon F1 brake, as the clutch plates are all carbon fibre, they will wear and change in dimension slightly as the clutch is used and heats up. This means the bite point will move as the clutches condition changes. The bite point is the position on the clutch’s travel where the clutch starts to engage and power starts to transmit. Albeit with a lot of slip, as the clutch is not yet fully engaged. This is the same on road cars, when at the lights you tend to lift the clutch to feel where it bites in order to be ready for a lightning start when the lights change.

From the steering wheel there’s a clutch or BPF button, this sets up the monitoring of the clutch movement, which is achieved from the clutch actuator, normally via a Hall Effect or induction type sensor. The driver releases the clutch paddle slowly and the system marks the point where the clutch bites. This needs to be completed after the clutch has been warmed up and no more burn outs are required in order not to move the bite point form additional heat or wear.

Clutches explained on “The Racers Edge”

Other Clutch Images